The piping Design Engineering course started in 2001. The course’s USP is the use of industrially experienced faculty with 15-30 years of experience teaching their expertise topic.

We have graduated approximately one hundred batches in the last 18 years and roughly 5,000+ piping engineering graduates who excel in their respective fields. Our graduates are working in all leading EPC MNC reputed organisations, e.g., Praj Industries, Petrofac, ACER, Jacobs, L&T, Thermax, Kirloskar, Triplan, Burn and Mcdonald, Alfa Laval, Technische, SUEZ, Technimont, Billfinger, etc.

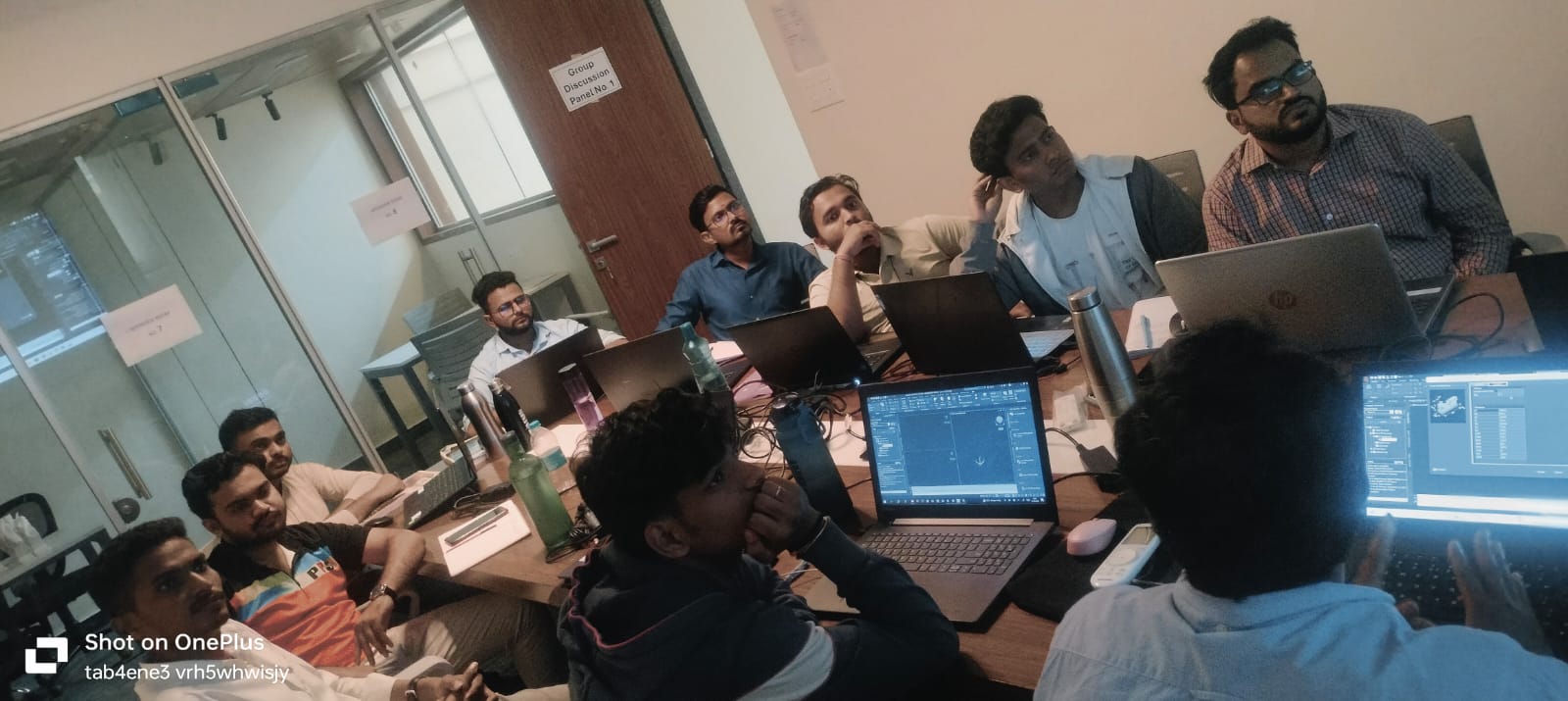

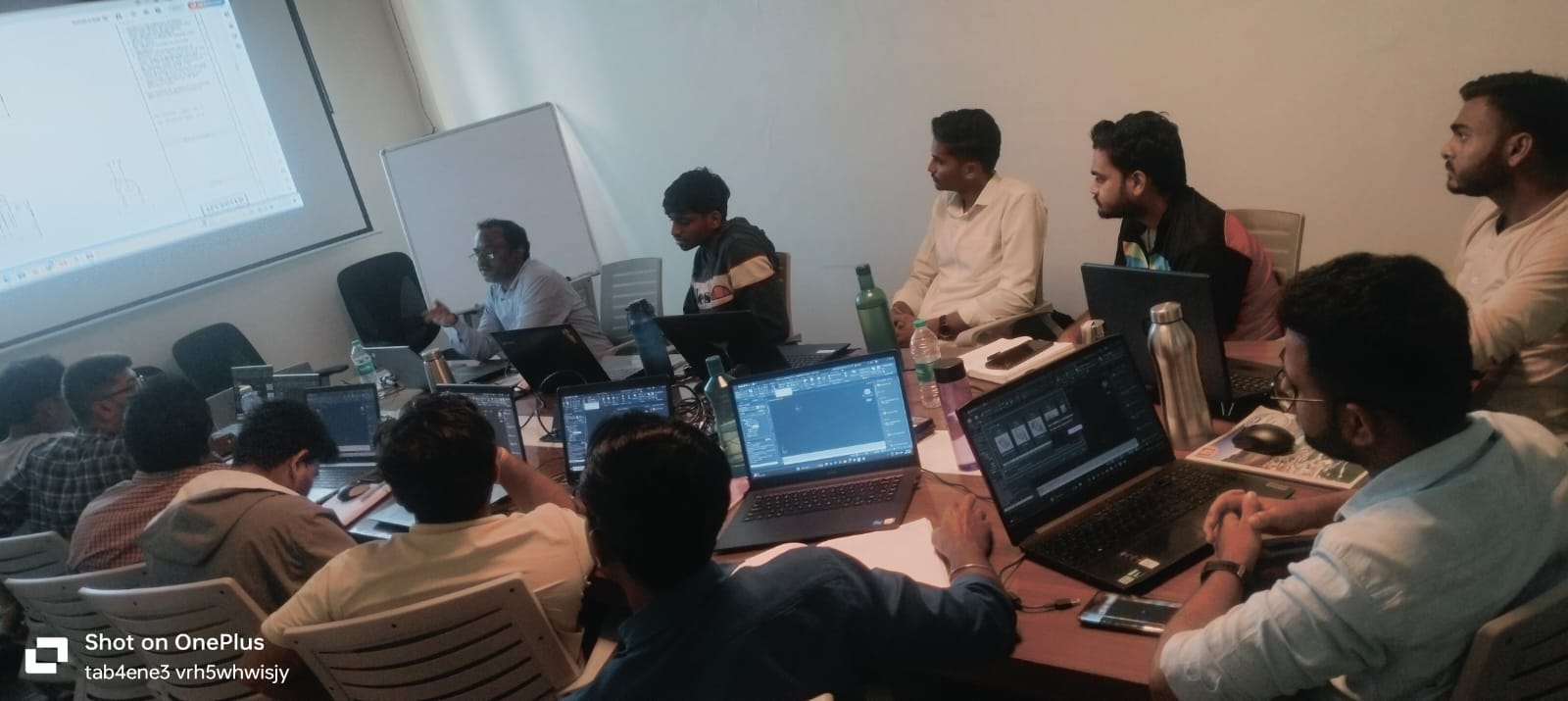

Our course caters to all industry needs with extensive software training.

The piping Design Engineering course started in 2001. The course’s USP is the use of industrially experienced faculty with 15-30 years of experience teaching their expertise topic.

We have graduated approximately one hundred batches in the last 18 years and roughly 5,000+ piping engineering graduates who excel in their respective fields. Our graduates are working in all leading EPC MNC reputed organisations, e.g., Praj Industries, Petrofac, ACER, Jacobs, L&T, Thermax, Kirloskar, Triplan, Burn and Mcdonald, Alfa Laval, Technische, SUEZ, Technimont, Billfinger, etc.

Our course caters to all industry needs with extensive software training.

WHAT IS PIPING ENGINEERING?

Every process plant needs a piping system to be designed with care. The performance of a plant depends on the efficient transport of process fluid through the pipes according to the material and energy balance for a process, and this requires systematic analysis and engineering design methods. Over the years, many such standards and practices for piping system design have evolved, and they are a significant engineering science. Every engineering and construction company will need a trained workforce to design a piping system. Our objective in starting this autonomous course is to impart this initial training.

Significance of

Piping Engineering

- The piping department of an engineering and construction company generally begins with the piping and instrumentation diagram (P&ID).

- The process department prepares a process flow sheet, which begins with the chemical reaction. After carrying out material and energy balance and equipment selection, the flow sheet is further utilised to prepare the first version of P&ID.

- One can now begin actual plant design. After completing the plot plan and equipment layout, the next step is to start designing a piping system for material transport.

- In our course, we will adopt a building block concept. We will begin with pipes selected by line sizing and the hydraulics of pumps and compressors used to transport material. These pipes are “connected” using pumps and compressors. Add to them the valves, safety devices, measuring instruments, and control components, and the first rough sketch of the piping structure will be complete.

- However, a scientific and systematic approach has been developed, and design codes and practices have evolved. They are used to follow a step-by-step procedure to develop a piping system structure.

- This course aims to teach students this systematic science. Engineers will only approve any structure if it has been analysed for stress, including the connecting components such as nozzles, flanges, pipe supports, etc.

- We will use pipe stress software to determine whether the designed structure can sustain static, dynamic, and combined stresses.

- General flowcharts for piping design procedures in parts at least are provided during the actual exercises.

- Thus, process and piping are becoming a significant force in engineering, procurement, and construction (EPC) companies as part of the Engineering IT culture being developed, justifying a growing need for qualified engineers to take up this profession.

Significance of

Piping Engineering

- The piping department of an engineering and construction company generally begins with the piping and instrumentation diagram (P&ID).

- The process department prepares a process flow sheet, which begins with the chemical reaction. After carrying out material and energy balance and equipment selection, the flow sheet is further utilised to prepare the first version of P&ID.

- One can now begin actual plant design. After completing the plot plan and equipment layout, the next step is to start designing a piping system for material transport.

- In our course, we will adopt a building block concept. We will begin with pipes selected by line sizing and the hydraulics of pumps and compressors used to transport material. These pipes are “connected” using pumps and compressors. Add to them the valves, safety devices, measuring instruments, and control components, and the first rough sketch of the piping structure will be complete.

- However, a scientific and systematic approach has been developed, and design codes and practices have evolved. They are used to follow a step-by-step procedure to develop a piping system structure.

- This course aims to teach students this systematic science. Engineers will only approve any structure if it has been analysed for stress, including the connecting components such as nozzles, flanges, pipe supports, etc.

- We will use pipe stress software to determine whether the designed structure can sustain static, dynamic, and combined stresses.

- General flowcharts for piping design procedures in parts at least are provided during the actual exercises.

- Thus, process and piping are becoming a significant force in engineering, procurement, and construction (EPC) companies as part of the Engineering IT culture being developed, justifying a growing need for qualified engineers to take up this profession.

Eligibility & Registration Procedure

- B.E./ B.Tech/ Engg Diploma: Mechanical/ Chemical & Allied/ Production/ Industrial

- Final Year Appearing Students

- Industry Professionals

- Others with relevant experience

- Admission form : https://docs.google.com/document/d/1CE85B_biU0Yr_2Nb4nc-nil8DeIFO8m2/edit?usp=sharing&ouid=114607714928590668519&rtpof=true&sd=true

- Fill out the admission form and print it out.

- Attach a photocopy of one qualification proof (degree/diploma certificate or mark sheet).

- Attach a photocopy of one proof of ID (Driving license, PAN Card, Aadhar Card, college ID card, etc).

- Affix 1 passport-size photographs.

- You can send the admission form along with documents for provisional admission to piping@vit.edu (Provisional confirmation on email will be given) and fial confirmation of admission after an online payment of 1st installment on 1st day of Batch starting.

- On first day of Batch starting you need to make online account with vit Pune and all payment will be done with same account.

Softwares

- Duration: 4 Months

- Days in a Week: Thursday To Sunday

- Time: 10.00 am to 5.00 pm

- Intake: 40 Students

- Duration: 6 To 8 Months

- Days In a Week: Saturday and Sunday

- Time: 10.00 am to 5.00 pm

- Intake: 40 Students

- Total Fees: ₹75000/- (Seventy Five Thousands only) including all taxes

0-Installement-Details

- 100% Placement Assistance

Recent Updates

FAQs

Yes, Installments allowed = Three (25000*3)

Provisional registration with admission form and email to piping@vit.edu

Final Registration on payment of ₹10000

Remaining ₹15000 after joining the course and after that every month end ₹25000/-

Send the scanned admission form to piping@vit.edu and get provisional and final confirmation of admission after a ₹10000 cash payment.

Yes, we have tied up with a private hostel 5-10 minutes’ walk from campus. After you confirm your registration for the course, we can share the hostel details with you.

We have found that students from South India miss their rice-based food. We have convinced one restaurant to make South Indian rice(rice is available in Pune) and curry specifically so South Indian students can happily complete the course.

FAQs

Yes, Installments allowed = Three (25000*3)

Provisional registration with admission form and email to piping@vit.edu

Final Registration on payment of ₹10000

Remaining ₹15000 after joining the course and after that every month end ₹25000/-

Send the scanned admission form to piping@vit.edu and get provisional and final confirmation of admission after a ₹10000 cash payment.

Yes, we have tied up with a private hostel 5-10 minutes’ walk from campus. After you confirm your registration for the course, we can share the hostel details with you.

We have found that students from South India miss their rice-based food. We have convinced one restaurant to make South Indian rice(rice is available in Pune) and curry specifically so South Indian students can happily complete the course.

Contact

Dr. Satchidanand R. Satpute

Course Coordinator | Piping Engineering Course

![]() piping@vit.edu

piping@vit.edu

![]() 7057107330

7057107330

Dr. M. P. Deosarkar

HOD, Dept. of Chemical Engineering

![]() 9224244626

9224244626

+91 7058432258

+91 7058432258